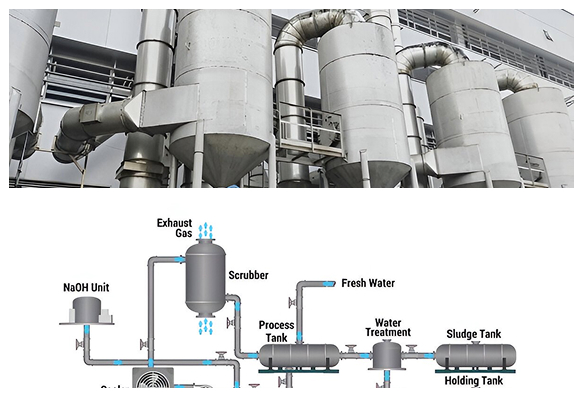

Scrubber Systems

Customized Gas Cleaning Solutions for Air Pollution Control

Shree Shakti Engineering Works offers engineered scrubber systems designed to control and neutralize acidic, basic, toxic, and particulate-laden gases before atmospheric release or recycling. Our systems are custom-built for chemical, pharmaceutical, agrochemical, and industrial emission control applications, ensuring compliance with CPCB / State PCB norms and client-specific emission limits.

We provide scrubbers suitable for a wide variety of gases, including HCl, SO₂, NH₃, Cl₂, NOₓ, HBr, and organic vapors — using single-stage or multi-stage treatment configurations.

Types of Scrubber Systems Offered

- Packed Bed Scrubber (Vertical / Horizontal)

- Venturi Scrubber – For fine particulate capture

- Multi-Stage Wet Scrubbers

- Dry + Wet Combo Scrubber Systems

- Fume Scrubbers for laboratory or pilot plants

- Caustic, Alkali, or Water Wash Scrubbers

- Dual Alkali Systems (for specialized neutralization)

System Components Supplied

- Scrubber Vessel / Column

- Mist Eliminator / Demister Pad

- Recirculation Tank / Pump Skid

- Instrumentation – Level, Temp, pH, Flow, DP

- Control Panel (Manual / Auto / PLC)

- Interconnecting Piping, Nozzles & Drain Systems

- ID Fan / Blower (with or without VFD)

- FRP / SS Ducting (optional)

- Chimney / Stack with Sampling Port

Design Inputs Required (From Client)

| Parameter | Required Details |

|---|---|

| Gas Flowrate | m³/hr or Nm³/hr |

| Gas Composition | Chemical names, concentrations |

| Inlet & Outlet Temp | °C |

| Inlet / Target Emission Levels | Required ppm/mg/Nm³ |

| pH Range & Solubility | For absorber liquid selection |

| Operating Pressure | Atmospheric / Slight Positive or Vacuum |

| Materials of Construction | SS304 / SS316 / FRP / PP+FRP / PVC / Alloy |

| Scrubbing Media | Water, Caustic, Lime, Acid, or Custom Neutralizer |

Design Specifications

| Flow Capacity | 100 m³/hr to 50,000+ m³/hr |

| Removal Efficiency | Up to 99.9% (depending on media) |

| Pressure Drop | Varies by packing and design |

| Temp Range | Up to 180°C (jacket) |

| MOC Options | Stainless Steel (SS304 / SS316) / PP-FRP, PVC-FRP, HDPE, MSRL / Hastelloy, Alloy 20 (for corrosive gases) |

| Tower Packing | PP / PVC / Ceramic / PTFE Rings |

| Available in Skid | Mounted Modular Systems for easy installation |

Design Codes & Standards

- ASME Section VIII, Div. 1 –For pressure-rated vessels

- IS 2825 – For structural and design compliance

- CPCB / GPCB Norms –Pollution control limits

- EN 13121 Guidelines

- Design validated for emission standards under site –specific operating conditions

Quality Control & Inspection

- Hydro & Pneumatic Testing

- DPT for Weld Joints

- Packing and internals inspection

- Blower trial & alignment testing

- pH / flow / conductivity sensor calibration (if included)

- Third-Party Inspections etc.

Optional Features / Add-ons

- Online pH Monitoring & Dosing Control

- Blower with Silencer / VFD Drive

- Flameproof Motor / Panel (if hazardous area)

- Vent Condenser or Knockout Drum

- Skid Mounting with Drainage Basin

- Stack with Sampler, Platform & Access Ladder

- Remote Data Logging or PLC-SCADA Integration

Industries Served

- Agrochemical & Pesticide Plants

- Pharmaceutical API Manufacturing

- Specialty Chemicals

- Dyes & Pigment Manufacturing

- Fertilizer & Acid Neutralization Plants

- Fume Extraction in Labs, Pilot Units

- Solvent Recovery / VOC Control Units