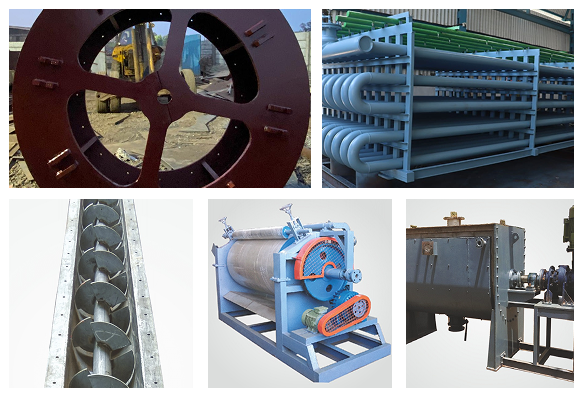

Custom-Made Equipment

Tailored Engineering Solutions for Specialized Process Needs

At Shree Shakti Engineering Works, we understand that not all industrial challenges fit into standard equipment categories. That’s why we specialize in the design, engineering, and fabrication of custom-made equipment tailored to your unique process, space, and performance requirements.

With deep expertise in mechanical design, metallurgy, process integration, and on-site fabrication, we help industries bridge the gap between concept and commercial operation — delivering fit-for-purpose, code-compliant equipment built to perform.

Types of Custom Equipment Supplied

- Pilot & Lab-Scale Equipment

- Modular Process Skids

- Compact Reactors / Heat Exchangers

- Non-standard Tanks / Silos / Hoppers

- Combination Vessels (e.g., Filter + Dryer)

- Custom Structural Frames & Platforms

- Column Internals, Custom Supports & Distribution Systems

- Utility Packages (Air, Water, Vacuum, Chemical Dosing)

- Vessels with Integrated Instrumentation Panels or PLC Control

Design Inputs Required (From Client)

| Parameter | Required Details |

|---|---|

| Application / Process Description | What the equipment must achieve |

| Capacity & Operating Conditions | Flow, Pressure, Temperature, Vacuum |

| MOC | SS304, SS316, Duplex, CS, Cladded, Hastelloy |

| Mounting / Space Limitations | Horizontal / Vertical / Modular / Skid-based |

| Accessories / Automation | Motors, Valves, Sensors, Electrical, etc. |

| Safety / Compliance Needs | GMP / cGMP / ATEX / IBR / PED |

| Documentation Requirements | Drawings, FAT, IQ-OQ, Datasheets, etc. |

Design Flexibility & Features

| Volume | From 5 Litres to 100 KL or custom dimensions |

| Orientation | Vertical, Horizontal, Mobile, or Modular |

| Materials | SS304, SS316L, SA516 Gr.70, Alloy Steel, Duplex, Cladded |

| Finish Options | Mirror / Grit / Epoxy / PTFE Lining |

| Fabrication Method | Shop-based or On-site (as per size) |

Design Codes & Standards

- ASME Section VIII, Div. 1 – Pressure Design

- IS 2825 / IS 803 / IS 10987 – Indian Standards

- GMP / cGMP Compliance – For pharma and food-grade systems

- PED / EN 13445 – European compliance (on request)

- WPS / PQR Qualified Welding Procedures

- Client-Specific SOPs or Custom Specs

Quality Control & Inspection

- Project-specific QA Plans

- Stage-wise Inspection (Raw Material to Final Assembly)

- Hydro / Pneumatic / Vacuum Leak Testing

- Internal Reports and Full Traceability

- TPI by TÜV, SGS, DNV, IRClass, CEIL, Chempro, or client’s own team

Optional Add-ons / Configurations

- Integrated Valves / Pumps / Skid Frames

- PLC / HMI Control Panels

- Load Cell & Automation Modules

- Structural Platforms with Access Safety

- VFD Panels, Flameproof Electricals

- FAT at Factory / SAT at Site

- 3D Modelling & Layout Simulation (if needed)

Industries Served

- Pharmaceuticals / Biotech

- Agrochemicals & Intermediates

- Oil & Gas Support Systems

- Specialty Chemical & Fine Chemicals

- R&D, Pilot Plants, and Lab Equipment

- Food, Nutraceuticals & Cosmetics

- EPCs & OEMs for Custom Modules