Turnkey Projects

Complete Design–Fabrication–Installation Solutions Under One Roof

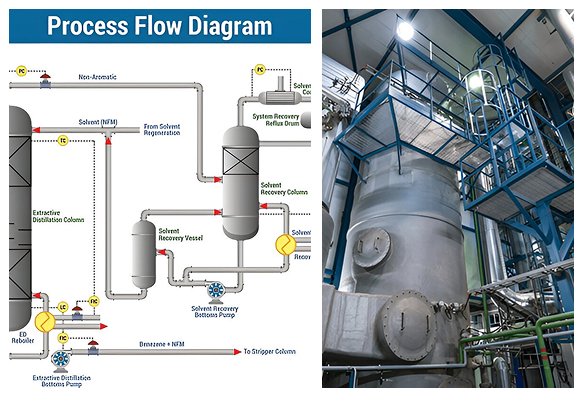

At Shree Shakti Engineering Works, we undertake turnkey projects for process industries requiring a single-window solution for equipment design, supply, fabrication, and site execution. From concept development to final commissioning, we offer end-to-end services for greenfield, brownfield, and expansion projects across India.

We combine our expertise in process equipment, mechanical engineering, and field fabrication to deliver customized, high-quality systems — on time and within budget.

Scope of Turnkey Execution

- Process Understanding & Layout Planning

- Detailed Engineering (Mechanical + Piping)

- Fabrication & Supply of Equipment ( Reactors, Heat Exchangers, Vessels, Tanks, Columns )

- Utility Systems & Packages ( Skid-mounted or distributed (Vacuum, Air, Heating, Scrubbing) )

- Structural Fabrication & Platform Assembly

- Piping (SS / CS / PPFRP) – Isometric & Erection

- Erection, Alignment & Site Welding

- Insulation, Painting, Cladding

- Instrumentation, Testing & Commissioning Support

- Documentation (Drawings, FAT, IQ-OQ, DQ, Final Dossier)

Turnkey Projects Executed

We have successfully executed multiple turnkey jobs for:

- Greenfield Agrochemical Plant Setup

- 500 KL SS Storage Tank Installation with Site Radiography

- Vacuum, Scrubbing & Reactor Systems Integration

- Skid-Mounted Solvent Recovery & Utility Modules

- Pilot Plant Assembly with Platform, Panel, and Piping

On-Site Fabrication Capabilities

- Tanks: Up to 500 KL (API 650, IS 803, IS 10987)

- Piping: CS, SS, HDPE/PPFRP – Butt Welded / Flanged

- Chimneys, Ducts, and Stack Fabrication

- Platform & Structural Support Fabrication

- Tie-up with NDT & TPI Agencies at Site

- Coordination with civil and electrical contractors (if required)

Standards & Compliance

- ASME Sec. VIII Div. 1 – Equipment design

- IS Codes, IBR, API 650, IS 2825 – Storage & Pressure Systems

- CPCB / GPCB Norms – Emission & Pollution Control

- GMP / cGMP Compliance – For pharma facilities

- PED / EN – (For export-based projects)

Quality Assurance

- Pre-dispatch inspection at factory

- Site inspection by QA/QC engineers

- NDT: RT, UT, DPT, MPI as per joint type

- Hydro / Pneumatic Testing

- Material & Welding Traceability

- TPI by TÜV, SGS, IRClass, CEIL, Chempro, or client-nominated bodies

Support & Documentation

- G.A. Drawings, Isometrics, P&IDs

- Mechanical & Electrical Load Data Sheets

- FAT / SAT Assistance

- Final DQ, IQ, OQ Documents

- Erection & Commissioning Logs

- Operator Training & Maintenance Support

Why Choose Shree Shakti for Turnkey Projects?

- In-house equipment manufacturing

- Site fabrication & erection capability

- Skilled fabrication & piping teams

- Engineering + Execution under one roof

- Quality-first approach with full documentation

- Flexible to work with EPCs, OEMs, and directly with end-users