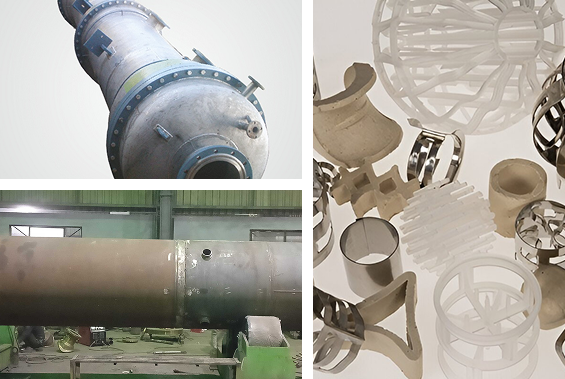

Distillation Columns

Engineered for Efficient Mass Transfer Applications with Precision-Fit Internals

Shree Shakti Engineering Works specializes in the design, fabrication, and supply of distillation and absorption columns, including a full range of mass transfer internals. Our columns are built for critical separation, recovery, and purification applications in chemical, petrochemical, pharmaceutical, and refinery industries.

We manufacture columns as per ASME, IS, and API standards, customized for client-specific throughput, pressure, and tray/packing configurations.

Types of Columns Offered

- Distillation Columns (Batch & Continuous)

- Absorption Columns / Scrubbers

- Stripping Columns

- Extraction Columns

- Packed Columns

- Tray Columns

- Combination Packed + Tray Columns

Column Internals Supplied

- Bubble Cap Trays

- Sieve Trays

- Valve Trays

- Packing Support Grids

- Liquid Distributors / Redistributors

- Packing Retainers

- Demister Pads / Mist Eliminators

- Feed Pipes, Downcomers, Chimney Trays

- Structured or Random Packing (Metallic / Plastic / Ceramic)

Design Inputs Required (From Client)

| Parameter | Required Details |

|---|---|

| Service Type | Distillation / Absorption / Extraction |

| Operating Pressure & Temp | Inlet / Outlet / Design limits |

| Diameter & Height | Or required throughput and separation duty |

| No. of Stages / Packing Height | Tray count or HETP for packed columns |

| Internals | Tray or Packing Type (if known) |

| MOC | SS304, SS316L, SA516 Gr.70, Duplex, etc. |

| Accessories | Manholes, Nozzles, Ladders, Platforms, etc. |

Design Specifications

| Diameter Range | 200 mm to 3000 mm |

| Height | Up to 30 meters (modular design available) |

| Pressure | Vacuum to 25 bar |

| Temperature | -20°C to 350°C |

| MOC | SS304, SS316, SS316L, SA516 Gr.70, Duplex, Cladded |

| Orientation | Vertical (standard), Horizontal (for special cases) |

| Finish | Grit Blasted, Pickled & Passivated, Painted, Mirror (pharma) |

Design Codes & Standards

- ASME Section VIII, Div. 1 –Pressure vessel design

- IS 2825 –Indian pressure vessel standards

- EN 13445 / PED –European design compliance

- Client-specific specifications for OEMs / EPCs / Consultants

Quality Control & Inspection

- WPS / PQR qualified welders

- Raw material traceability (MTCs)

- Weld joint NDT: DPT, RT, UT

- Hydro / Pneumatic testing

- TPI by leading agencies

- Visual inspection, dimensional checks, internal report documentation

| Optional Features & Accessories | Industries Served |

|---|---|

| Demister Pads / Mist Eliminators | Chemical & Agrochemical Plants |

| Reboilers / Condensers / Knockout Drums | Pharmaceuticals & API Units |

| Skid-Mounted Assembly | Petrochemical Complexes |

| Vents, Sample Nozzles, Instrumentation Ports | Oil & Gas Processing |

| Platforms, Ladders, Lifting Lugs | Refineries & Intermediates |

| Removable Packing Sections | Food, Flavors & Fragrance Recovery Units |

| Manways with davit arms | Solvent Recovery / Acid Gas Removal |