Design & Engineering

Design & Engineering

At Shree Shakti Engineering Works, our Design & Engineering division is led by a team of qualified professionals including mechanical design engineers, metallurgists, and certified welders. We specialize in the engineering and fabrication of customized chemical process equipment, with a strong emphasis on design accuracy, code compliance, and long-term durability.

Our engineering capabilities are backed by licensed design software, a deep understanding of international codes, and years of proven experience in delivering high-quality, compliant equipment. We design and fabricate in accordance with the following standards:

- ASME Section VIII, Division 1 – Pressure Vessel Design

- TEMA – Shell & Tube Heat Exchangers

- API 650 / IS 803 – Aboveground Storage Tanks

- IS 10987 – Underground Storage Tanks

- IS 2825 / IBR – Non-Boiler & IBR Pressure Vessels

- IS 875 / IS 1893 – Wind & Seismic Load Analysis

- Client-specific & International Standards – As per project requirement

With adherence to these standards, we ensure that every piece of equipment we produce is engineered to perform safely and reliably, even in the most critical process conditions.

In-House Licensed Design & Drafting Software

We utilize a combination of licensed tools and custom design spreadsheets to ensure engineering precision and fabrication compatibility:

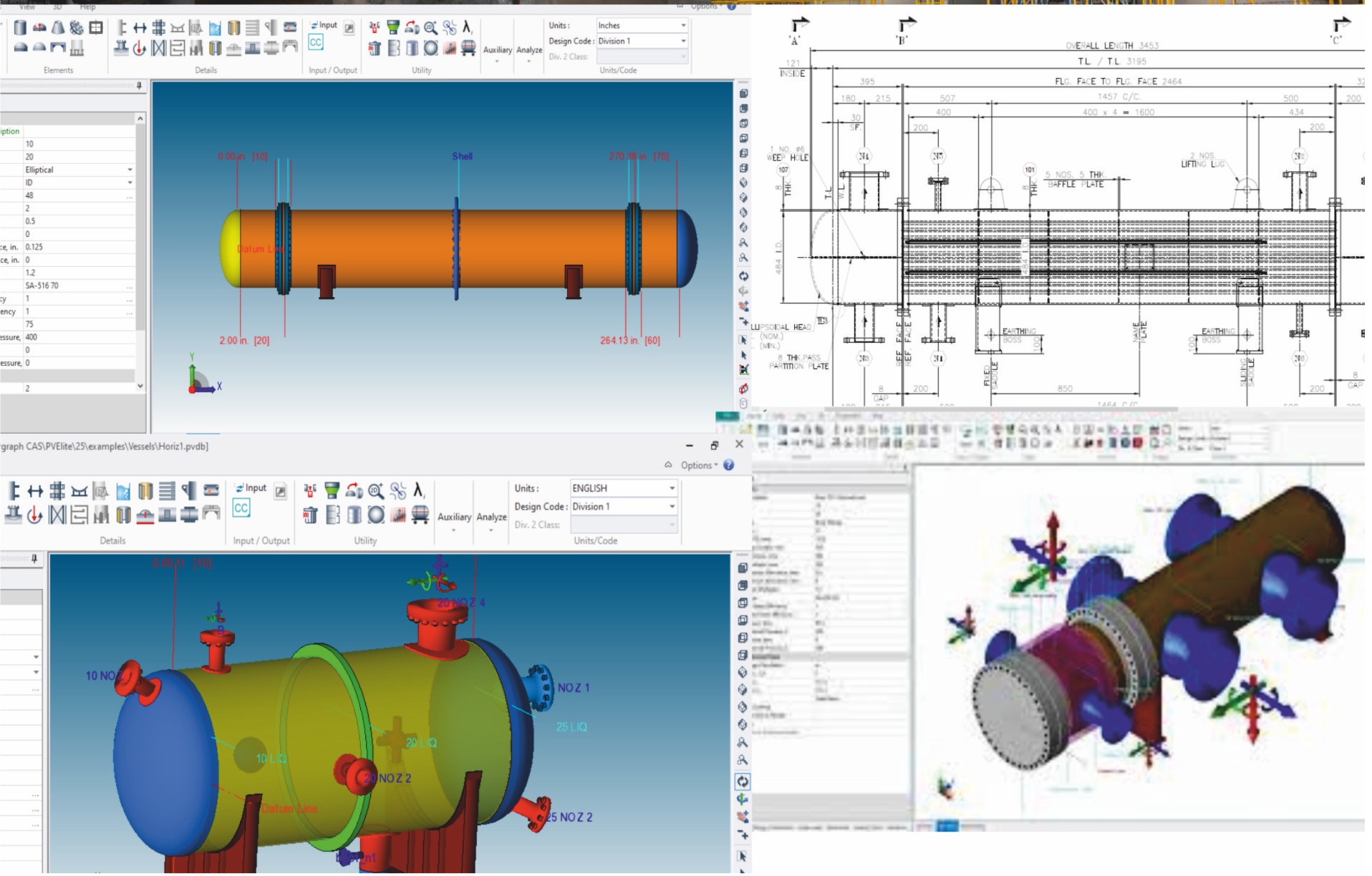

1. PV Elite®

Used for detailed design and analysis of:

- Pressure Vessels and Heat Exchangers

- Tubesheets and Non-Circular Vessels

- Saddles, Lugs, Legs, Trunnions, and Skirts

- Transportation and Shipping Load Analysis

- Wind and Seismic Loads (Global Codes)

- MAWP, Corrosion Allowance, and Retirement Limits

2. AutoCAD 2026

- Advanced 2D and 3D drafting capabilities that enable us to produce highly accurate technical drawings and layouts for a wide range of engineering applications.

3. Inventor 2026

- A powerful 3D mechanical design and documentation platform used for developing complex assemblies, creating parametric models, and streamlining the product development cycle from concept to production.

4. Inventor Nastran 2026

- An integrated simulation tool offering robust Finite Element Analysis (FEA), enabling us to test and validate design integrity, structural performance, and real-world conditions—before physical prototyping.

5. AutoCAD Plant 3D

- A specialized software for process plant design, including intelligent piping and instrumentation diagrams (P&IDs), equipment layouts, and piping models. Ideal for chemical, pharmaceutical, and industrial plant projects.

6. Custom Spreadsheet Tools

We have developed in-house spreadsheet tools tailored for mechanical design calculations, MOC (Material of Construction) selection, template-based documentation, and component sizing. These tools help us:

- Speed up repetitive design tasks

- Maintain consistency across projects

- Ensure compliance with relevant codes and standards

- Customize outputs for client-specific requirements

To deliver reliable and efficient solutions, we combine industry-standard software with our own in-house developed spreadsheet tools. These custom tools support fast and accurate mechanical design, material selection, and documentation—especially for non-standard and tailor-made equipment. By blending proven technology with smart automation, we ensure every project is executed with precision, speed, and full technical compliance—giving our clients confidence in both the process and the outcome.

Design Support from Associates

We also collaborate with specialized design partners using advanced platforms:

- NozzlePRO – Finite Element Analysis (FEA) for stress-critical zones

- HTRI® –Thermal design and performance validation for Heat Exchangers

- SolidWorks® / Inventor® –3D Modelling, Assembly Visualization, Layout Simulation

Our Promise

Every design at Shree Shakti is validated for functionality, safety, and manufacturability. With a strong grip on both mechanical and thermal design, and strict adherence to project-specific standards, we ensure that the equipment we deliver is engineered to perform, built to last.